Products & Services

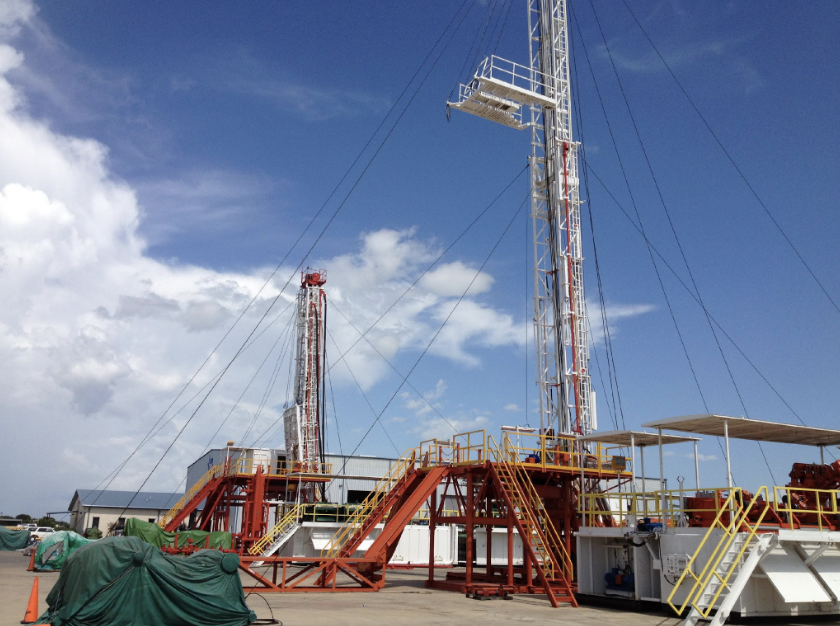

Fully Rig Packages - Rigs Operational & Engines Spare Parts

As dedicated dealers in rig manufacturing, we're not just offering drilling rigs; we're delivering a complete spectrum of solutions that encompass every facet of rig operations. At Rinato Service & Supply, we proudly provide an extensive range of drilling rig components, expendables, and spare parts that are essential for seamless drilling operations.

A Holistic Approach to Rig Solutions:

- Rig Manufacturing Expertise: Our reputation as rig manufacturing specialists speaks volumes about our commitment to delivering rigs that are designed for performance and durability.

- Beyond the Rig: We understand that a drilling operation comprises a multitude of components. From mud pumps to BOP's, and centrifuges to other mission-critical equipment, we have your needs covered.

- Expendables and Spare Parts: Ensuring uninterrupted operations is paramount. That's why we offer expendables and spare parts that are specifically curated to maintain and enhance the efficiency of your rigs.

Empowering Your Drilling Operations: Your One-Stop Solution for Rig Manufacturing and Components

Your Trusted Partner: With an unwavering commitment to quality, safety, and customer satisfaction, Rinato Service & Supply stands as your trusted partner. We're not just delivering products; we're delivering peace of mind, knowing that your drilling operations are backed by the best.

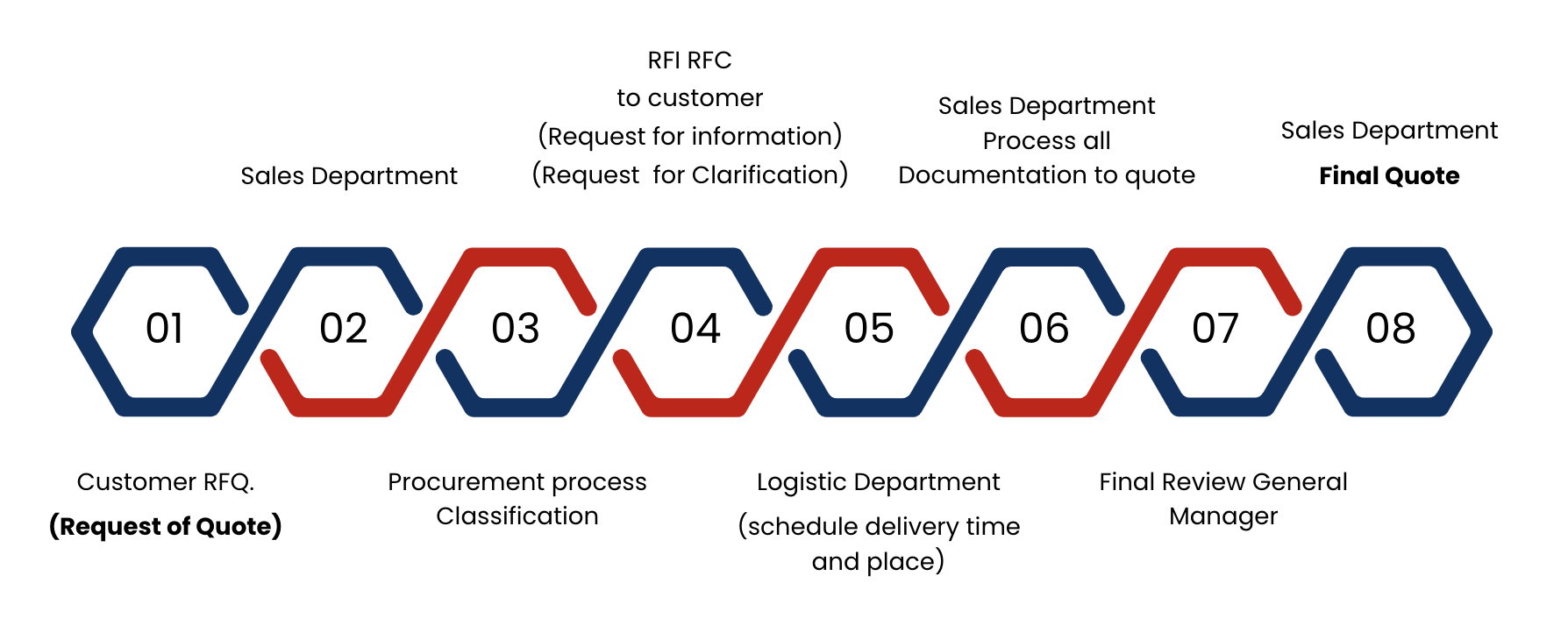

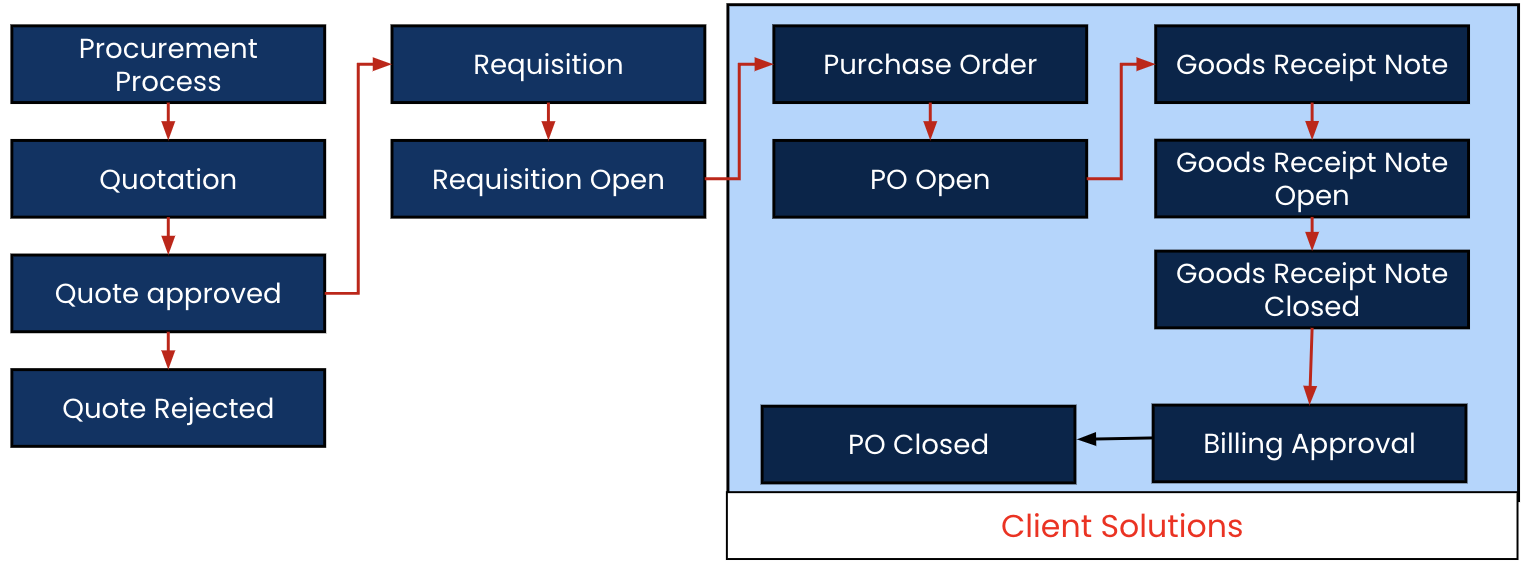

Procurement Process

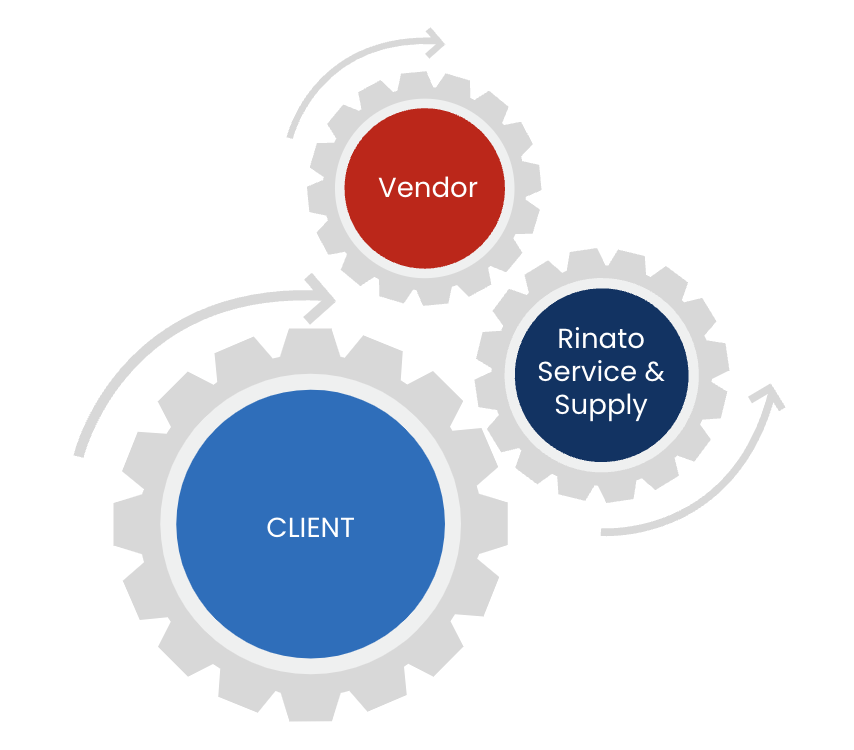

Supply Chain Management (SCM)

We offer this service trough our procurement department. Offering experienced logistics consultants to review, evaluate and analyze your supply chain processes to optimize your operation.

- Receipt of Purchase Order.

- Supplier Verification.

- PO delivery term follow trough.

- Vendor Performance Analysis

- Partial Inspections of PO (in situ)

- Receipt of Merchandise against purchase order.(Warehouse Receipt)

- Quality control of the product to receive and confirmation of Serial and part number against PO.

- Photographic report of PO.

- Acceptance of Merchandise to enable billing.

- Daily reports of goods receipt vs quality processes.

The gear missing in your procurement service. We can manage all the requirements required to complete your Supply Chain Process.

Creating the complete connection between you the Customer and the Supplier.

Solutions

- Inspecting

- Reporting

- Online Warehousing follow 24hr/7

- Online photographic Reporting

- Online Status change

- Customized reporting fitted as your needs

Supply Chain Management (SCM)

STANDARD FOLLOW SCM PROCESS

We can provide up to date process information on any purchase we also offer an option to

tailored you own process as your Needs, so NOTHING WILL BE MISSING!

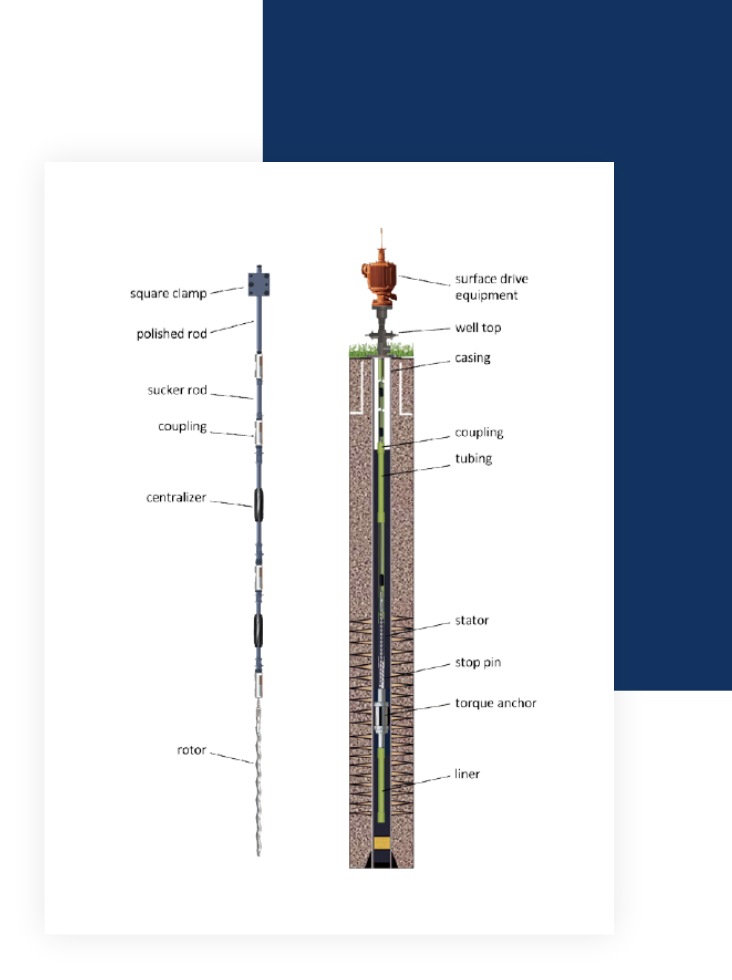

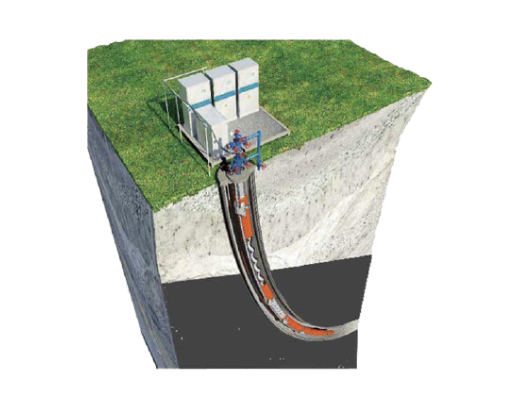

Progressive Cavity Pump

The PC pump is also named progressive cavity pump, it consists of a stator and a rotor, the helical interference of the both parts forms a series of continuous sealed cavities, and the medium transmission is then realized through the rotor rotational movement.

PCP Down-hole Pump is to connect the stator and rotor respectively to the ends of the oil tube and the sucker rod, the drive head on ground can drive the rotor through the sucker rod and the down-hole liquid can then be lifted to the ground.

Progressive Cavity Pump

Technical characteristics of PCP Down-hole Pump

- Lower early investment

- Compared with electric submersible pump, hydraulic piston pump and beam-pumping unit, PCP Down-hole pump's first investment is smaller.

- Higher efficiency, energy saving and lower maintenance The load of PCP Down-hole pump is stable during operation, the mechanical loss is less, and the pump efficiency can reach 45%-65% and the highest can reach 70%, but that of the plunger-type pumping unit is only about 30%.

- Compact structure

Control Cabinet

Aiming at different surface drive devices, Subtor supplies completely the frequency conversion control cabinet and permanent magnet motor direct-driven control cabinet for controlling the start-up, stop, and speed regulation of motor, automatically displaying, recording the current and voltage of the PCP down-hole pump in regular production, the automatic protection function of overload and underload can guarantee normal production of oil wells.

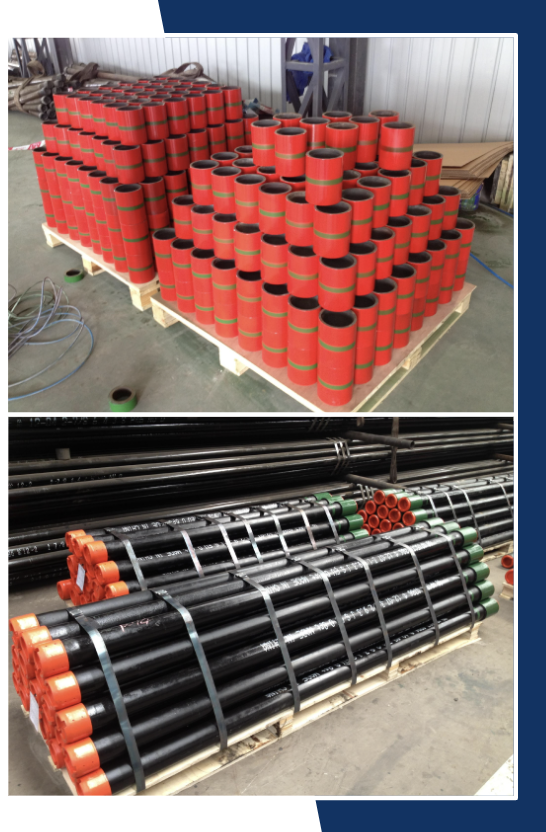

Drill Pipes & OCTG

Are you in search of superior-quality oilfield drilling and production equipment that adheres to the stringent standards set by the American Petroleum Institute (API)? Look no further! At [Your Company Name], we specialize in providing top-tier drill pipes, drill collar heavy weights, tubing, and casing that meet and exceed API specifications including API Spec 5D, API 7-1, and API 5CT.

Elevate Your Drilling Operations Partner with [Your Company Name] to elevate your drilling operations with equipment that stands up to the rigors of the oilfield. Whether you're seeking standard solutions or customized options, we have the expertise to cater to your specific requirements.

Are you in search of top-notch Oil Country Tubular Goods (OCTG) couplings that meet the highest industry standards? Look no further! At Rinato Service & Supply, we take immense pride in offering a complete lineup of OCTG couplings, ranging from 2-3/8” to 36”, meticulously crafted to adhere to the stringent guidelines of API 5CT specification.

Elevate Your Connections When it comes to establishing robust connections in the oilfield, choosing the right couplings is paramount. At Rinato Service & Supply, we understand your needs and provide tailored solutions to match. Whether you require couplings for conventional operations or specialized projects, our range has you covered.

Experience Excellence in OCTG Couplings Collaborate with Rinato Service & Supply and experience excellence in every coupling. Our commitment to quality, compliance, and customer satisfaction sets us apart.

Sucker Rods & Couplings Supply

Steel Sucker Rods, Drive Rods, Pony Rods, are Manufactured from micro-alloyed, Modified special quality in hot roll carbon or alloy steel with Both ends upset by automatic high-speed hot Forging. Bar and sucker rod dimensions and tolerances conform to API Spec 11B, latest edition, and AISI Steel Products Manual. Sucker rods are available in 5/8” (15.88 mm), 3/4” (19.05 mm), 7/8” (22.23 mm), 1” (25.40 mm) and 1 1/8” (28.58 mm). Drive Rods® for Progressing Cavity Pump application are available in 1” (25.40 mm), 1 1/4” (31.75 mm), and 1 1/2” (38.10 mm) body diameter and in 25’ (7.62 m) lengths.

The rod connector is welded with the rod body through friction welding followed by heat treatment and rolling depression. The sucker rods have the advantage of stable mechanical property and improved fatigue strength.

The thread is machined using a compression and rolling machine resulting in a continuous metal fiber of the thread. This technique improves thread strength and decreases stress concentration. The center diameter of the thread is controlled strictly, which makes the load to be evenly taken by the thread teeth thus increasing load capacity and preventing loosening of the connection.

The rod body, connector and coupling are made of quality 20CrMo and 35CrMo quenched and tempered alloy steel, which improves overall mechanical properties. High coaxial-it between the connector thread and the rod body gives the sucker rod high bending strength.

Oil and Grease Supply

It is a meticulously manufactured oil designed for mixed fleet engines, engineered to deliver optimal performance in both Gasoline and Diesel engines, operating under diverse service conditions. This superior blend is crafted using top-quality raw materials and high-grade additives, resulting in a host of valuable benefits:

- Exceptional control of piston deposits at high temperatures, thanks to the advanced detergents and dispersants that prevent harmful carbon buildup and maintain engine cleanliness.

- Effective foam protection provided by the specialized anti-foaming agents, ensuring smooth lubrication and preventing air entrapment that could lead to engine inefficiencies.